Navigating the Lathe Market: What to Consider Before Buying a Used Lathe

Capable of lasting over a decade and having the potential to save you thousands if bought used, it’s no surprise lathes are one of the top CNC machines purchased second-hand. Lathes, especially CNC, are quite expensive, with some going for over $100,000. With almost everything online these days, it’s easier than ever to find the lathe machine that’ll fit your machining and business needs. Whether you’re a seasoned machinist or new to the world of lathes, understanding what to look for when purchasing a second-hand lathe is crucial. Join us as we provide insights into the different types of lathes and explore what you should consider before purchasing a second-hand lathe for sale.

Machine Condition

The condition of the used lathe is paramount. Inspect the machine thoroughly, paying attention to wear and tear, rust, and overall cleanliness. Check critical components that are prone to wear and tear like the bed, headstock, tailstock, and carriage for signs of damage. There are specific components related to the type of lathe you are purchasing that should be inspected prior to purchase. An example is the spindle, which is critical to a Lathe machine. You would want to run the spindle at high speed to see if you can catch any odd noises. Another example are the bed ways as they are responsible for the accuracy of the cuts. This part of the machine should be parallel so that the carriage is able to also move with the axis of the spindle. Keep in mind, it is normal to have wear and tear on these components with a used machine. You just want to make sure the wear is not so severe that it would impact the machine’s performance.

Request video and pictures of the machine. This helps give you an idea of the lathe machine’s overall condition before you even set up an in-person visit. A video of the machine running will be essential if you cannot make a trip to see the machine. Ask for maintenance records to get a sense of how well the lathe has been cared for over the years.

Type of Lathe Machine

Understanding the specific type of lathe you need is essential. Most lathe machines that are sold today are CNC, which can be a great asset to your manufacturing facility, as it increases productivity. There are several types of industrial lathes, each designed for different applications:

- Manual Lathes: These are the traditional lathes operated by machinists. They are versatile and often used for simple to moderately complex machining tasks.

- CNC Lathes: Computer Numerical Control (CNC) lathes offer precision and automation. Different types include vertical turret lathes, Swiss lathes, engine lathes, and multi-axis lathes. Your choice will depend on your production needs.

Precision & Tolerance

Does it have a CNC (Computer Numerical Control system? CNC Lathe machines are preferred in the manufacturing industry as they automate jobs and are great for mass production. For CNC lathes, accuracy and precision are vital. Check if the lathe maintains the specified tolerances. Inspect the spindle and cutting tools to ensure they are in good condition.

Machine History

Request information about the machine’s history, including its previous applications and usage patterns. Knowing the kind of work it has done in the past can provide insights into its wear and tear. How old is the lathe and how many hours has it logged? Lathe machines will last decades if they are well taken care of. If the machine has a CNC system, you should be able to keep it up-to-date with the latest software.

Documentation

Ensure that you receive all relevant documentation, including manuals, maintenance records, and any warranties that may still be valid. Maintenance records will allow you to see the service history of the used lathe machine and how well it’s been maintained. This can show you what, if any minor or major repairs have been done on the lathe machinery over its history. This can also put your mind at ease, giving you confidence that the used lathe equipment you’re interested in will perform well for years to come.

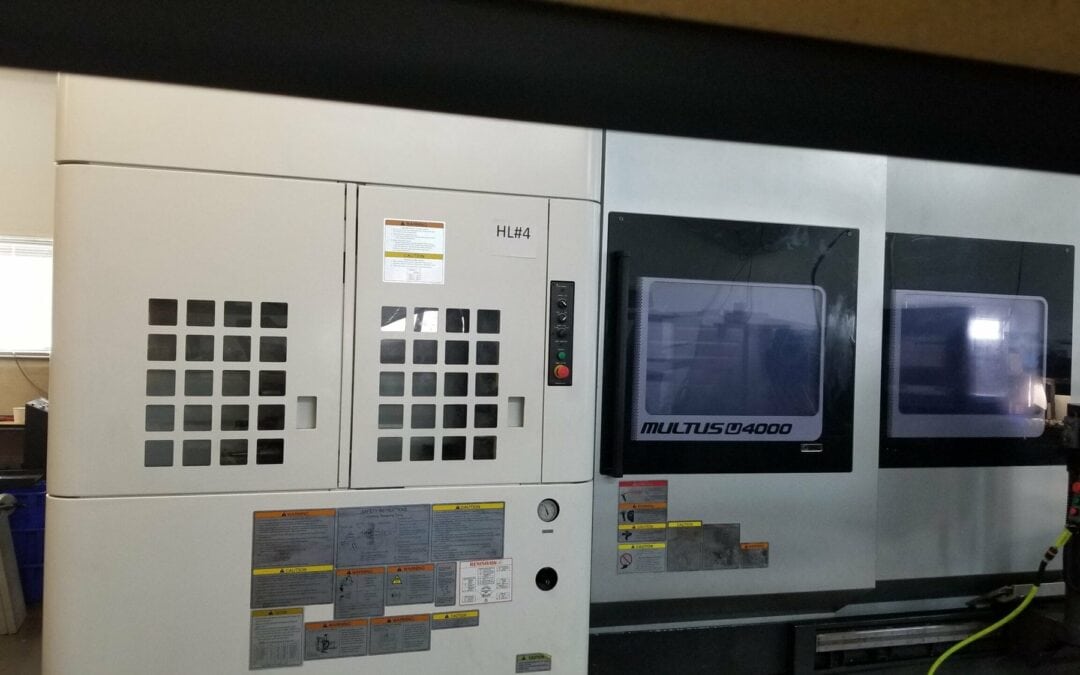

Manufacturer & Model

Consider well-known lathe manufacturers and models, as they often come with a reputation for quality. Research the model to understand its specifications and capabilities.

Tooling & Accessories

Evaluate the included tooling and accessories. A lathe with a comprehensive set of tooling can save you time and money on additional purchases.

Are You Interested in Purchasing a Used Lathe?

We can help! Revelation Machinery can always help you find what you need! If you have any questions about lathe machines or need to find a specific brand/type, please feel free to contact us!

Price & Negotiation

Compare prices of similar used lathes for sale in the market to ensure you’re getting a fair deal. Don’t hesitate to negotiate with the seller, especially if you uncover any issues during inspection.

Rigging & Transportation

Consider the logistics of moving the used machine lathe to your facility. Ensure you have the necessary equipment and resources for rigging and transportation. What are the costs to transport this machine to you if need be? You will want to make sure you understand the full cost of purchasing the machine, including the cost of transporting it to your facility.

Compliance with Safety & Regulatory Standards

Before purchasing a second-hand lathe, ensuring the lathe machine is compliant with safety and regulatory standards is of the utmost importance to not only maintain a safe working environment, but to adhere to legal requirements as well. Does the used lathe meet OSHA (Occupational Safety and Health Administration) standards? While CNC lathe machines should not have issues meeting safety regulations, this is something that could come up if it is an older lathe machine.

You’ll also want to verify safety features available on the used lathe and evaluate the lathe’s overall operational safety. Ensure the lathe’s electrical system meets local electrical codes and standards, noise levels comply with local regulations, and that dust and fume control systems are in place, including ventilation and filtration systems, to meet environmental and safety standards. After purchasing a used lathe, establish a regular inspection and maintenance schedule to ensure ongoing compliance with safety regulations. Periodic inspections and maintenance are essential for keeping the lathe safe and operational.

Lathe Machine Inspection

Before purchasing a second-hand lathe, inquire about scheduling an in-person inspection of the used lathe machine. If you’re not well-versed in lathe machinery, consider hiring a professional inspector to accompany you during the inspection. Their expertise can help identify potential issues that may not be apparent to a novice. If an in-person inspection is not possible due to timing or location of the lathe equipment, reach out to the used equipment dealer and request photos and videos of the lathe machine running. Reputable used equipment companies would be happy to send over what you need to ensure you’re confident with the lathe equipment and will be happy long after your purchase.

Conclusion

In conclusion, purchasing a second-hand lathe can be a cost-effective and practical choice for many machining operations. However, thorough research, diligent inspection, and careful consideration of your specific needs are essential to ensure you make a sound investment. No matter what you’re in the market for, a well-maintained and properly chosen lathe can become a valuable asset in your machining arsenal, contributing to your productivity and success.

With all of the above in mind, make sure to find a reputable used machinery dealer to assist in your search for a used lathe machine. At Revelation Machinery, we offer a large selection of used machinery and top-tier industrial equipment for sale. With a regularly-updated inventory of used lathe machines for sale including manual lathes, and CNC lathes such as multi-axis lathes, swiss-type lathes, vertical turret lathes, and used engine lathes for sale, our team is experienced and ready to help you find the right machine for your facility. Contact our equipment experts today and let us know how we can assist with your machinery needs or view our lathes for sale now!